This article traces the shift in TKA alignment strategies from mechanical to personalized approaches (kinematic, restricted, functional), enabled by robotic systems like MAKO, ROSA, NAVIO, and CUVIS. It introduces the MISSO Robotics System as a next-generation tool offering precision and adaptability using AI, while noting the need for further clinical validation.

Dr. Kunal Aneja, Department of Orthopaedics, Max Super Speciality Hospital, and Naveda Healthcare Centres, New Delhi, India. E-mail: drkunalaneja@gmail.com

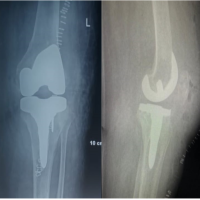

Total knee arthroplasty (TKA) has witnessed remarkable advancements over the past two decades, from refined implant designs to improved surgical workflows. Yet, the pursuit of optimal alignment and true kinematic restoration remains elusive. Restoring each patient’s unique anatomy and joint mechanics continues to challenge conventional approaches. This ongoing dilemma has shifted attention toward more personalized strategies in TKA [1].

The traditional mechanical alignment (MA) approach positions components perpendicular to the mechanical axis, achieving symmetrical gaps through ligament releases. Historically favored for its potential to enhance implant longevity, this standardized methodology may compromise the restoration of natural knee kinematics [2]. This realization has spurred the development of personalized alignment strategies, including kinematic, inverse kinematic, restricted kinematic, and functional alignment (FA) approaches [3].

These patient-specific techniques aim to recreate the individual’s pre-arthritic anatomy by precisely restoring native limb alignment, joint line orientation, and physiological soft-tissue tension while minimizing ligamentous disruption [4]. Implementing such customized alignment protocols presents considerable technical challenges with conventional instrumentation, particularly regarding precise intraoperative decision-making and the lack of real-time feedback on tissue balance and resection accuracy.

This paradigm shift toward anatomical restoration highlights the essential role of robotic-assisted systems, such as MISSO Robotics, which offer the precision and reproducibility required to execute these advanced alignment concepts while maintaining implant stability and longevity.

Anatomic alignment (AA)

First proposed by Hungerford and Krackow in the 1980s, AA aims to achieve a joint line oriented in 2–3 of valgus relative to the mechanical axis [5]. Modern prostheses now incorporate this principle through built-in three degrees coronal obliquities. The surgical technique for AA closely follows that of MA, differing primarily in the intentional deviation from neutral alignment [5].

Kinematic alignment (KA): Restoring native anatomy

First described by Howell et al. (2008), KA restores native knee anatomy by replicating pre-arthritic joint surfaces, unlike MA, which enforces neutral positioning [6]. Using calipered instrumentation (“true KA”), it involves articular-parallel bone cuts, wear compensation, and minimal soft-tissue release. While KA better preserves natural kinematics, concerns remain about mechanical axis deviations and stability in extreme anatomies, representing a shift from standardized to patient-specific reconstruction [7].

Inverse kinematic alignment (iKA)

This alignment strategy prioritizes the restoration of the pre-arthritic tibial joint line while adjusting the femoral distal/posterior cuts for ligament balance. In practice, iKA involves the following key steps:

- Preserves tibial anatomy

- Prevents over-resection

- Independently balances flexion/extension gaps [8].

Robotic assistance enhances precision by enabling real-time intraoperative adjustments, overcoming limitations of conventional instrumentation. By maintaining native tibial obliquity and optimizing femoral component positioning, iKA reduces post-operative complications while achieving physiological joint kinematics [3].

Restricted kinematic alignment

Unrestricted KA remains controversial due to elevated implant stresses (24.8–32.2% increase in moderate/severe varus knees) [3] and potential polyethylene wear [8]. Vendittoli’s restricted KA protocol establishes safe zones (±5° femoral/tibial cuts, ±3° HKA angle) as a hybrid approach between MA and KA [9]. This technique preserves KA’s anatomical principles while mitigating excessive stresses by primarily adjusting tibial component positioning to control coronal alignment and joint line obliquity [3].

FA: A hybrid approach

FA integrates kinematic principles with dynamic soft-tissue balancing through robotic assistance. This approach:

- Restores pre-arthritic alignment

- Achieves precisely balanced flexion-extension gaps (±1–2° accuracy)

- Optimizes mediolateral tension [8].

Robotic systems facilitate this process by enabling real-time, quantifiable adjustments in all anatomical planes, ensuring reproducible non-neutral alignments (±2° precision) and minimizing limb alignment outliers. FA preserves native knee kinematics, reduces soft-tissue releases, and maintains physiological joint mechanics [3].

While FA represents a promising shift toward personalized TKA, it is important to note that not all studies have shown substantial clinical differences between kinematic and MA strategies. Although early trends favor improved kinematic restoration and joint function, definitive long-term superiority of FA in terms of functional outcomes and implant longevity remains under investigation [10].

This balanced perspective acknowledges the potential of FA while underscoring the need for continued high-quality research.

The CPAK classification provides a systematic framework for categorizing knee phenotypes based on the native alignment and joint line obliquity. Developed by MacDessi et al. [11], CPAK is instrumental in identifying the pre-arthritic anatomical configuration of the knee, which is essential for implementing patient-specific alignment strategies. In the context of robotic-assisted TKA, the CPAK classification aids in accurately assessing the native knee phenotype, enabling surgeons to plan precise, individualized bone cuts that restore the original kinematic profile. Robotic systems, such as MISSO Robotics, may enhance this process by providing real-time feedback and adaptive intraoperative adjustments, which might ensure that the restored alignment closely matches the patient’s original anatomy. By incorporating CPAK-guided planning, robotic-assisted TKA facilitates the preservation of native knee mechanics, potentially leading to improved functional outcomes and patient satisfaction.

The significant anatomical variability among individuals necessitates a paradigm shift from standardized techniques to personalized alignment strategies in TKA. The key scientific rationale for this approach includes:

- Improved patient satisfaction: Advanced navigation systems provide intraoperative guidance to accurately restore native joint alignment and physiological soft-tissue balance. This preservation of natural kinematics improves joint functionality, potentially leading to superior patient-reported outcomes and increased rates of post-operative satisfaction [10].

- Optimized biomechanical performance: Personalized alignment techniques demonstrate superior replication of native knee biomechanics compared to MA. By maintaining physiological joint line orientation during weight-bearing activities, this approach reduces shear forces at articulating surfaces and implant-bone interfaces, thereby decreasing stress concentrations that may compromise long-term implant performance [12].

- Physiological soft-tissue preservation: The personalized alignment methodology precisely restores constitutional joint line orientation while maintaining native ligamentous laxity patterns. This anatomical approach eliminates the need for soft-tissue releases, preserving the knee’s natural stabilizing structures and proprioceptive feedback mechanisms [12].

Robotic-assisted TKA utilization has grown substantially in recent years. These systems were specifically engineered to enhance alignment precision and prosthetic positioning through three key technological features: (1) real-time intraoperative navigation, (2) dynamic calibration, and (3) haptic feedback mechanisms [13]. By improving bone resection accuracy and minimizing alignment outliers, robotic TKA aims to extend implant longevity. Clinical evidence confirms that proper mechanical axis restoration is correlated with reduced polyethylene wear rates and a decrease in revision surgery incidence [14]. Several robotic platforms have achieved widespread clinical adoption, including: MAKO (Stryker), ROSA (Zimmer Biomet), NAVIO/CORI (Smith and Nephew), and CUVIS (Curexo, South Korea,). These systems demonstrate superior performance compared to conventional instrumentation, offering: Enhanced implant positioning accuracy, reduced soft-tissue disruption, more precise bone resection, and improved gap balancing [13].

However, limitations remain:

Limited haptic feedback

- Some semi-active systems provide limited tactile feedback, potentially affecting bone preparation precision compared to fully active systems [15].

Bulky hardware and setup complexity

- Some platforms require large operating room footprints and complex setups, which limit maneuverability and increase turnover time between cases [16].

Compatibility issues

- Not all systems are universally compatible with all implant designs or manufacturers, reducing flexibility for surgeons [15].

Procedural risks

- Potential need for intraoperative conversion to conventional technique [14]

These limitations highlight the need for next-generation systems that optimize cost efficiency, workflow integration, adaptive surgical planning, and user-friendly interfaces.

The MISSO Joint Robotic System (Meril Healthcare Pvt. Ltd., India) represents a transformative innovation in computer-assisted orthopedic surgery, establishing new standards for precision in joint replacement procedures. As a fully autonomous robotic platform, MISSO is designed to achieve submillimeter accuracy (≤0.5 mm) in bone resection [17]. According to early testing, the system can potentially adjust the plan intraoperatively based on ligament tension data, an innovation that, if validated, would set it apart from current systems.

- Precision bone resection technology: The system incorporates an active robotic milling mechanism with proprietary vibration-dampening technology that achieves submillimeter (≤0.5 mm) accuracy in bone preparation [17]. This precision is maintained through real-time optical tracking that continuously monitors and adjusts the milling process [18]. The robotic arm’s high-frequency vibration control enables smooth surface preparation even in complex geometric features such as femoral box cuts and tibial keels [17].

- Dynamic intraoperative adaptability: A network of multiple sensor arrays provides continuous data acquisition throughout the procedure, allowing for real-time modification of the surgical plan based on quantitative soft-tissue tension measurements (0.5 mm resolution) and actual tissue response. This adaptive capability enables the system to compensate for anatomical variations encountered during surgery while maintaining the planned alignment targets [17].

- Advanced safety architecture: The platform features a six-degree-of-freedom robotic arm with multiple redundant safety systems, including force-limiting algorithms and collision detection sensors with millisecond-range emergency braking capabilities [17]. These systems work in concert to prevent excessive bone resection and protect surrounding soft tissues while maintaining surgical precision [17,18].

- Integrated verification systems: A closed-loop control mechanism continuously compares actual bone resections against pre-operative plans, providing real-time feedback to the surgical team. This verification process occurs simultaneously with the milling operation, ensuring dimensional accuracy is maintained throughout the procedure without requiring additional verification steps [15].

Although the MISSO joint robot system presents compelling theoretical advantages, its clinical utility must be substantiated through robust empirical evaluation. Existing robotic-assisted orthopedic platforms have demonstrated improved alignment precision; however, their impact on long-term implant survivorship, functional outcomes, and patient-reported measures remains incompletely characterized and continues to be actively explored.

Critical research priorities

Head-to-head comparative studies: Well-designed, prospective controlled trials are essential to rigorously compare MISSO with current robotic systems, focusing on parameters such as alignment precision, surgical accuracy, and functional recovery. Evaluation of implant longevity: It is critical to investigate whether MISSO’s personalized alignment methodologies enhance implant longevity and resistance to wear over time. Assessment of soft-tissue preservation and function: Research should elucidate whether MISSO’s minimally invasive and tissue-conserving approach results in improved proprioception, restoration of physiological kinematics, and better post-operative mobility. Health economic analyses: Comprehensive cost-effectiveness assessments are necessary to determine if MISSO optimizes surgical workflow, minimizes operative time, and reduces hospitalization durations, thereby offering economic advantages.

The integration of novel robotic surgical systems into mainstream orthopedic practice requires rigorous regulatory evaluation and evidence-based clinical validation. The MISSO platform has achieved preliminary certification through India’s Central Drugs Standard Control Organization. It is currently undergoing evaluation for CE marking and U.S. Food and Drug Administration clearance – processes that typically demand extensive biomechanical testing and clinical data submission.

Current evidence generation for this technology remains in the preliminary stages. For comprehensive clinical adoption, future investigations should incorporate the following study design:

Multicenter randomized controlled trials comparing robotic-assisted versus conventional techniques

- Long-term survivorship analyses (minimum 5-year follow-up)

- Health economic evaluations assessing cost-effectiveness ratios

- Surgeon learning curve quantification through procedural metrics.

The implementation of personalized alignment strategies in TKA represents a significant advancement in optimizing functional outcomes and extending implant longevity. Robotic-assisted technologies have been pivotal in improving surgical accuracy; however, current systems continue to exhibit limitations in adaptability, procedural efficiency, and cost-effectiveness. Robotic-assisted systems, such as MISSO Robotics, play a critical role in executing these personalized techniques with greater precision and reproducibility. MISSO’s advanced capabilities, including artificial intelligence-driven intraoperative adaptability and real-time tissue balance assessment, theoretically address the limitations of existing robotic platforms. However, its clinical efficacy and long-term benefits must be validated through extensive multicenter trials. Future research should focus on assessing MISSO’s impact on implant survival, functional recovery, and cost-effectiveness. Until robust clinical evidence emerges, MISSO remains a promising innovation in the pursuit of truly personalized TKA, with the potential to redefine alignment paradigms and improve patient-specific outcomes in knee arthroplasty.

References

- 1.Cretu B, Costache M, Cursaru A, Serban B, Spiridonica R, Popa M, et al. Restoring anatomical features in primary total knee arthroplasty. Cureus 2023;15:e40616. [Google Scholar | PubMed]

- 2.Massé V, Cholewa J, Shahin M. Personalized alignment™ for total knee arthroplasty using the ROSA® knee and persona® knee systems: Surgical technique. Front Surg 2023;9:1098504. [Google Scholar | PubMed]

- 3.Lustig S, Sappey-Marinier E, Fary C, Servien E, Parratte S, Batailler C. Personalized alignment in total knee arthroplasty: Current concepts. SICOT J 2021;7:19. [Google Scholar | PubMed]

- 4.Available from: https://www.zimmerbiomet.com/content/dam/zb-corporate/en/education-resources/surgical-techniques/specialties/knee/persona-the-personalized-knee/1578.2-glbl-en%20persona%20kinematically%20aligned%20tka%20surgtech-digital1.pdf Accessed on 25 April 2025 [Google Scholar | PubMed]

- 5.Hungerford DS, Krackow KA. Total joint arthroplasty of the knee. Clin Orthop Relat Res 1985;192:23-33. [Google Scholar | PubMed]

- 6.Howell SM, Kuznik K, Hull ML, Siston RA. Results of an initial experience with custom-fit positioning total knee arthroplasty in a series of 48 patients. Orthopedics 2008;31:857-63. [Google Scholar | PubMed]

- 7.Hiranaka T. Current concept: Personalized alignment total knee arthroplasty as a contrast to classical mechanical alignment total knee arthroplasty. Arthroplasty 2024;6:23. [Google Scholar | PubMed]

- 8.Minoda Y. Alignment techniques in total knee arthroplasty. J Joint Surg Res 2023;1:108-16. [Google Scholar | PubMed]

- 9.Almaawi AM, Hutt JR, Masse V, Lavigne M, Vendittoli PA. The impact of mechanical and restricted kinematic alignment on knee anatomy in total knee arthroplasty. J Arthroplasty 2017;32:2133-40. [Google Scholar | PubMed]

- 10.Alhifzi Z. Systematic review and meta-analysis of long term outcomes and innovations in total knee arthroplasty: Kinematic, personalized knee vs. Conventional. Orthop Rev (Pavia) 2024;16:122318. [Google Scholar | PubMed]

- 11.MacDessi SJ, Griffiths-Jones W, Harris IA, Bellemans J, Chen DB. Coronal plane alignment of the knee (CPAK) classification. Bone Joint J 2021;103-B:329-37. [Google Scholar | PubMed]

- 12.Rivière C, Harman C, Boughton O, Cobb J. The kinematic alignment technique for total knee arthroplasty. In: Rivière C, Vendittoli PA, editors. Personalized Hip and Knee Joint Replacement. Ch. 16. Cham, CH: Springer; 2020. [Google Scholar | PubMed]

- 13.Pailhé R. Total knee arthroplasty: Latest robotics implantation techniques. Orthop Traumatol Surg Res. 2021;107:102780. [Google Scholar | PubMed]

- 14.Saber AY, Marappa-Ganeshan R, Mabrouk A. Robotic-assisted total knee arthroplasty. In: StatPearls. Treasure Island, FL: StatPearls Publishing; 2023, 2025. [Google Scholar | PubMed]

- 15.Sousa PL, Sculco PK, Mayman DJ, Jerabek SA, Ast MP, Chalmers BP. Robots in the operating room during hip and knee arthroplasty. Curr Rev Musculoskelet Med 2020;13:309-17. [Google Scholar | PubMed]

- 16.Souders CP, Catchpole KR, Wood LN, Solnik JM, Avenido RM, Strauss PL, et al. Reducing operating room turnover time for robotic surgery using a motor racing pit stop model. World J Surg 2017;41:1943-9. [Google Scholar | PubMed]

- 17.Available from: https://www.merillife.com/assets/pdfs/medical-devices/misso-robotic-system-1719659207pdf.pdf Accessed on 25 April 2025 [Google Scholar | PubMed]

- 18.Available from: https://www.merillife.com/blog/medtech/misso-the-surgical-assistant-robot-that-is-a-cut-above Accessed on 25 April 2025 [Google Scholar | PubMed]