This article shows how the use of simple instruments can help you overcome broken component incarceration.

Dr. Zyad Ayman Taha, Department of Orthopaedics, University Hospital of Florence, Italy. E-mail: zyadaymant@gmail.com

Introduction: The rising use of modular implants in revision total knee arthroplasty offers surgeons greater flexibility in addressing bone defects and achieving uniform gaps compared to monoblock counterparts. However, this enhanced functionality brings specific complications such as loosening and breakage at component coupling sites, leading to challenges due to mechanical failures and suboptimal fixation. Extracting broken components during revision surgery poses a significant challenge, prompting innovative techniques to facilitate extraction.

Case Report: We present a rare case of modular femoral component mechanical failure in a 69-year-old male, manifesting as left knee instability and acute pain while walking 4 years following revision of total knee replacement due to infection. Radiographs revealed mechanical failure of the Sigma Total Condylar-III Revision prosthesis bolt, with intra-operative extraction efforts complicated by a lodged broken bolt. Despite initial challenges, successful extraction was achieved using mosquito forceps and a universal nail extractor.

Conclusion: This case highlights the importance of documenting rare instances of mechanical failure in modular implants, emphasizing the need to understand prevalence rates and various surgical techniques for implant extraction. Our experience underscores the utility of the universal nail extractor as a valuable tool in managing difficult implant removal during revision surgery. Surgeons must remain vigilant and innovative in addressing challenges encountered during modular implant revisions.

Keywords: Modular implants, revision total knee arthroplasty, mechanical failure, and implant extraction.

The utilization of modular implants in the setting of revision of total knee arthroplasty (RevTKA) is steadily increasing mainly due to their clear advantages over monoblock counterparts. These modular implants provide surgeons greater flexibility to achieve uniform gaps and address bone defects. However, this enhanced functionality is accompanied by specific complications associated with modular design, such as loosening and breakage at component coupling sites, which are susceptible to mechanical failure due to suboptimal fixation. Hence, the extraction of broken components presents a significant challenge for surgeons in the setting of revision due to mechanical failure of the implant. Several techniques have been documented to facilitate the extraction of broken implant components. In this paper, we present a case of modular femoral component failure in a 69-year-old male who presented with left knee instability and acute pain while walking 4 years following RevTKA secondary to infection. Radiographs showed a bolt head extruding from the femoral component and two semicircular radio-opaque structures in the knee joint, suggesting a mechanical failure of the sigma total condylar-III (TC3) revision prosthesis bolt. Intra-operatively, the broken bolt head and broken adapter engaging the bolt head were readily removed. However, the remaining portion of the broken bolt was lodged in the adapter, resisting removal attempts with bone nibblers or drilling. Eventually, the broken part was extracted using mosquito forceps, gradually rotating the broken bolt out of the sleeve threads of the adapter. Despite efforts, the distal portion of the broken femoral adapter remained firmly fixed to the femoral sleeve, resisting removal with dedicated implant extraction instruments. Surprisingly, the universal nail extractor proved to be the solution, enabling successful extraction.

A 69-year-old male presented to our clinic with left knee instability and pain during movement, especially when standing up from a seated position 4 years following RevTKA using the SIGMA® TC3 Revision Knee System. The primary TKA was performed 10 years before the revision surgery due to infection. This patient had a body mass index of 30 kg/m2 and presented with comorbidities including diabetes, hypertension, ischemic heart disease, and epilepsy. Radiographs showed a bolt head extruding from the femoral component and two semicircular radio-opaque structures in the knee joint, suggesting a mechanical failure of the SIGMA® TC3 Revision Knee System Femoral Component’s bolt (Fig. 1). A diagnosis of mechanical implant failure was made after a thorough work-up to rule out an infection or any periprosthetic fracture and subsequently the patient was scheduled for implant removal and revision arthroplasty.

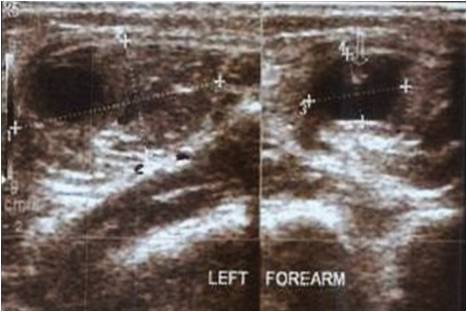

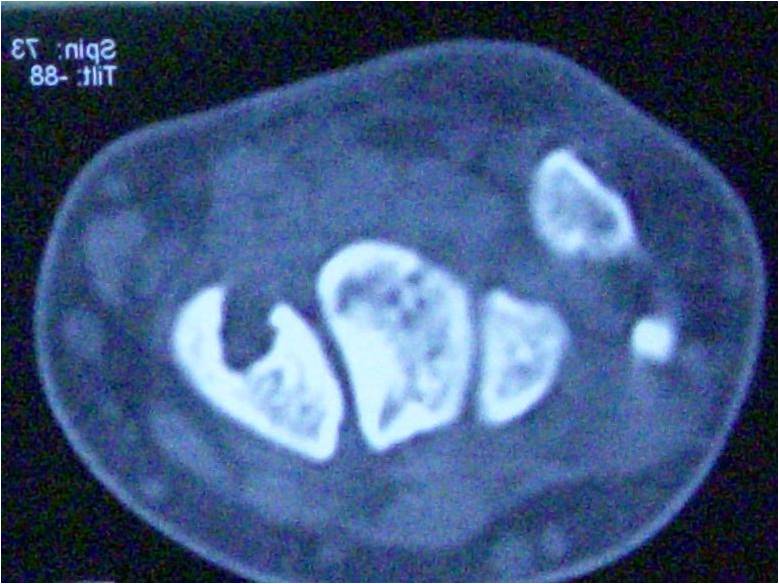

Intraoperatively, thickened black synovium suggesting metallosis was noted. The joint fluid appeared normal further ruling out an active infection. The tibial base plate was well fixed to the bone. The broken bolt and adapter at the femoral component-sleeve junction were visualized. Two semicircular screw threads from the adapter were seen floating in the joint space. The broken bolt head and the adapter end engaging it were readily extracted along with the two semicircular sleeve threads. The remaining part of the broken bolt was incarcerated to the remaining part of the broken adapter and attempts to remove it with bone nibblers or by drilling proved to be futile. Finally, the broken part was removed using mosquito forceps – slowly rotating the broken bolt out of the sleeve threads of the adapter (Fig. 2). The distal portion of the broken femoral adapter was rigidly fixed to the femoral sleeve and all attempts to remove it using the dedicated implant extraction instruments failed. The universal nail extractor unexpectedly proved to be the key to successful extraction. It was carefully introduced into the femoral canal, and with gentle yet firm back-hammering, the adapter was successfully extracted (Fig. 3). The tibial base plate and femoral sleeve were well fixed to the bone and thus were retained. The femoral component was fixed to the femoral sleeve with a new bolt and adapter. The insert was changed.

Post-surgery the patient was mobilized with full weight bearing from the next day and a range of motion (ROM) of 0–120° was achieved. Post-operative radiographs showed good alignment of the implants (Fig. 4).

The TC3 Revision Total Knee System (DePuy, Warsaw) is one of the most used revision implants worldwide. The femoral component in the TC3 is connected to the femoral sleeve or stem through a femoral adapter and corresponding femoral adapter locking bolt. In this paper, we present a case of mechanical failure of the femoral component of this system with breakage of both the femoral adapter and the locking bolt, both of which proved difficult to extract. During revision TKA, increasing levels of prosthetic constraint may be required to maintain stability of the knee joint. However, this additional constraint increases stress at the modular junction of the implant, rendering these implants more prone to fatigue failure. In addition, the removal of such broken implants may pose a challenge to the surgeon. Modular junction failure of the femoral component has been reported in scientific literature. Ihekweazu et al. documented four instances of femoral modular junction failures in Sigma TC3 RP implant (DePuy, Warsaw). Breakage of the femoral adapter and bolt were reported, but implant extraction was not discussed [1]. Similarly, Baral et al. reported a case of a broken femoral adapter and bolt in Sigma TC3 implant (DePuy, Warsaw) [2]. Mulpur et al. reported modular femoral component failure of a TC3 implant (DePuy, Warsaw). They reported disengagement and migration of the stem locking bolt into the joint cavity. Both the femoral component and stem were loose and were revisioned [3]. Lim et al. described five cases of locking bolt disengagement from the stem-condyle junction of the femur component from the TC3 implant (DePuy, Warsaw). All five cases had to undergo re-revision TKA [4]. Other authors reported a case with loosening of the locking bolt from a Total Condylar III implant (DePuy, Warsaw) [5]. Westrich et al. reported three cases of loosening and migration of the locking screw in Insall-Burstein II Constrained Condylar Knee (Zimmer, Warsaw) with press-fit femoral stems [6]. Some case reports also described locking bolt disengagement in the Insall-Burstein II prosthesis, with the bolt causing acute locking episodes of the knee [7]. Some authors described cases of failure at the taper lock of modular stemmed femoral implants [8, 9]. Woodgate et al. reported a case of mechanical failure of an S-ROM revision total knee prosthesis (DePuy, Warsaw) following a history of falls on a wet floor. The femoral and tibial components at the modular metaphyseal sleeve-stem junction were fractured and full re-revision was required [10].

The case presented here is a rare case of mechanical failure of the Sigma TC3 revision prosthesis. There is a need to document similar cases to understand the prevalence of this problem and the different surgical techniques used to overcome difficult implant extraction. In this report, we describe our experience in removing incarcerated broken components during the extraction of broken bolts and adapters. The universal nail extractor serves as a great tool for difficult implant removal and should be kept on standby for all revision cases.

This case highlights the value of utilizing innovative techniques, such as the universal nail extractor, to facilitate the extraction of broken implant components. By documenting and sharing experiences with difficult implant extractions, clinicians can enhance their understanding of different surgical approaches, ultimately improving patient outcomes in the management of modular implant failures.

References

- 1.Ihekweazu U, Courtney PM, Baral EC, Austin MS, McLawhorn AS. Modular junction fractures in a modern rotating-platform knee arthroplasty system. Arthroplast Today 2019;5:43-8. [Google Scholar]

- 2.Baral EC, McLawhorn AS, Wright TM, Su EP. Fracture of the femoral adapter bolt and taper adapter in a modern rotating platform knee arthroplasty. Arthroplast Today 2017;3:229-33. [Google Scholar]

- 3.Mulpur P, Jayakumar T, Masilamani AB, Hippalgaonkar K, Reddy AV. Unusual failure of modular TKA prosthesis and screw migration following revision total knee arthroplasty. J Orthop Case Rep 2022;12:25-9. [Google Scholar]

- 4.Lim LA, Trousdale RT, Berry DJ, Hanssen AD. Failure of the stem-condyle junction of a modular femoral stem in revision total knee arthroplasty: A report of five cases. J Arthroplasty 2001;16:128-32. [Google Scholar]

- 5.Ahn JM, Suh JT. Detection of locking bolt loosening in the stem-condyle junction of a modular femoral stem in revision total knee arthroplasty. J Arthroplasty 2010;25:660.e11-3. [Google Scholar]

- 6.Westrich GH, Hidaka C, Windsor RE. Disengagement of a locking screw from a modular stem in revision total knee arthroplasty. A report of three cases. J Bone Joint Surg Am 1997;79:254-8. [Google Scholar]

- 7.Nadkarni JB, Carden DG. Acute locking in revision total knee arthroplasty due to disengagement of the locking screw. Knee Surg Sports Traumatol Arthrosc 2005;13:190-2. [Google Scholar]

- 8.Issack PS, Cottrell JM, Delgado S, Wright TM, Sculco TP, Su EP. Failure at the taper lock of a modular stemmed femoral implant in revision knee arthroplasty. A report of two cases and a retrieval analysis. J Bone Joint Surg Am 2007;89:2271-4. [Google Scholar]

- 9.Yeramosu T, Ahmad W, Solanki S, Satpathy J. Fatigue failure of semiconstrained total knee replacement: Magnetic resonance imaging diagnosis with tips and tricks for extraction and reconstruction. Arthroplast Today 2022;18:143-8. [Google Scholar]

- 10.Woodgate IG, Rooney J, Mulford JS, Gillies RM. Mechanical failure of revision knee prosthesis at both femoral and tibial modular metaphyseal stem junctions. J Orthop Case Rep 2016;6:40-3. [Google Scholar]